Inspecting commercial buildings and homes using a thermal imaging camera is a powerful and noninvasive means of monitoring and diagnosing the condition of buildings. Thermal imaging technology has become one of the most valuable diagnostic tools for building inspections. A thermal imaging camera can identify problems early, allowing them to be documented and corrected before becoming more serious and more costly to repair.

Thermal imaging cameras are the perfect tool for locating and identifying building failures because they make the invisible visible. On a thermal image, problems seem to jump right out at you. A thermal imaging camera is the one tool that really lets you SEE it all.

A thermal image that includes accurate temperature data provides building experts with important information about the insulation conditions, moisture ingress, mold development, electrical faults, the presence of thermal bridges and the conditions of HVAC systems.

A building diagnostics inspection with a thermal imaging camera can help:

Thermal imaging cameras are such a valuable and versatile tool that it is not possible to list all the applications. New and innovative ways of using the technology are being developed every day.

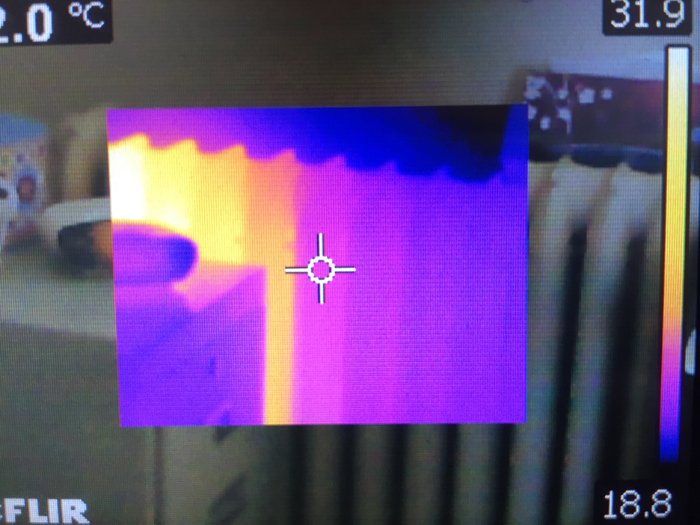

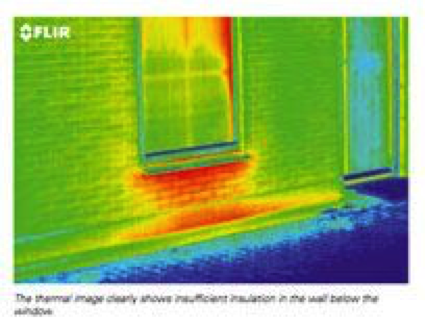

Thermal imaging is an outstanding tool to locate building defects such as missing insulation and condensation problems.

When using a thermal imaging camera to find missing insulation or energy losses, the difference in temperature between the inside of the building and the outside should be preferably at least 10 AÌ‚°C.

Air leaks lead to higher energy consumption and often cause problems with the ventilation system in homes. Air leaks can also lead to condensation in the construction, which in its turn can cause a poor indoor climate.

Moisture damage is the most common form of deterioration for a building. Air leakage can cause condensation to form within walls, floors, or ceilings. Wet insulation takes a long time to dry and becomes a prime location for mold and fungi.

Scanning with a thermal imaging camera can locate moisture that creates an environment conducive to mold. One might smell its presence, but not know where it is forming. A thermal survey will determine where moist areas are located that can lead to serious mold which can lead to health issues.

Moisture can be difficult to spot and the trick is to make the construction change temperature. Materials with moisture will then be clearly visible as they change temperature much slower than dry materials. Where other methods only measure the temperature in one spot, thermal imaging cameras can scan an entire area rapidly.

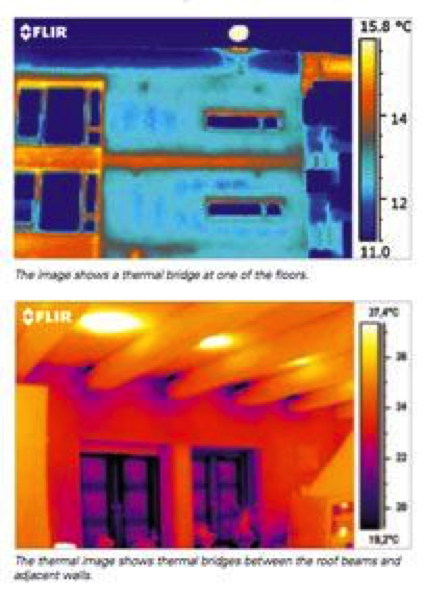

Other applications include the location of thermal bridges, which indicate spots in a building where energy is being wasted.

Other applications include the location of thermal bridges, which indicate spots in a building where energy is being wasted.

Typical effects of thermal bridges are:

District heating systems distribute heat, often steam, that is generated in a centralized location for residential and commercial heating requirements.

A thermographic survey can easily detect defects in pipes or tubes of any underground heating system. A thermal imaging camera can help to identify the exact location of the defect so that repair works can be minimized.

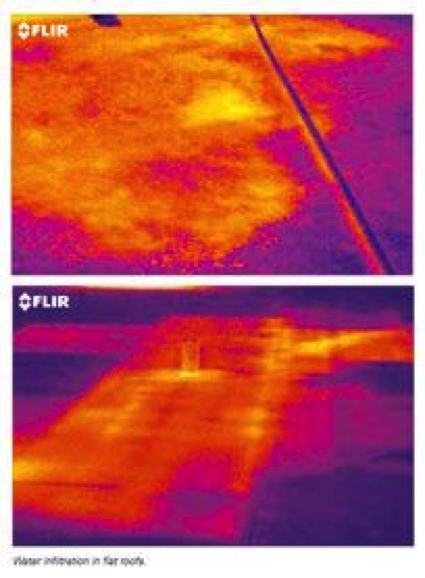

Thermal imaging is also used to detect water infiltration in flat roofs.

Water retains heat longer than the rest of the roofing material and can easily be detected with a thermal imaging camera very late in the evening or at night after the rest of the roof has cooled down.

Tremendous savings can be made by repairing wet areas rather than replacing the entire roof.

Thermal imaging is an easy-to-use tool to find and check pipes and tubes for leaks, even when the water pipes are laid in the floor or under plaster. The heat of the pipes radiates through the surface and the pattern can be easily detected with a thermal imaging camera.

Thermal imaging is an easy-to-use tool to find and check pipes and tubes for leaks, even when the water pipes are laid in the floor or under plaster. The heat of the pipes radiates through the surface and the pattern can be easily detected with a thermal imaging camera.

Thermal imaging technology is also used for quality assurance and the inspection of new buildings and homes.

During construction-drying, thermal images make it possible to determine the progress of the drying procedures so that necessary measures can be taken to speed up the drying process.

If this process can be accelerated and it can be proven, with the help of a thermal imaging camera, that the construction is totally dry, the building can be surrendered faster to the client.

Thermal imaging provides valuable information during the renovation of buildings and monuments. Framework constructions hidden by mineral plaster can become clearly visible in a thermal image. It can then be decided whether exposure of these structures is useful. The detachment of plaster from walls can also be located in a very early stage so that preservation measures can be taken.

Thermal imaging is a perfect tool to detect blocked or broken pipes and other plumbing related issues. Even if the pipes are laid under the floor or inside a wall it can be possible to determine the exact location of the problem by having hot water flowing through the pipes.

The heat will radiate and the problem area will become clearly visible on a thermal image.

Heating, Ventilation and Air-Conditioning (HVAC) systems need to be well maintained. They need to deliver air at the correct humidity and temperature and filter any indoor pollutants. Thermal imaging can help to determine whether HVAC systems are operating properly. When working incorrectly they can cause poor indoor air quality.

Every building also contains a lot of electrical installations. Thermal imaging can also be used to scan electrical cabinets, fuses, connections, etc.

By detecting problems that are invisible to the naked eye the problem can be repaired. If left unchecked, electrical problems can cause high temperatures. Furthermore, sparks can fly which might set the surroundings on fire.

Paul was so thorough and knowledgeable on the inspection of our house we were selling that we had no worries hiring him to inspect the house we were buying also.

As a property investor we have used many different inspectors in the past. But now we only call Mr. Andrusiw for all of our properties to get a clear and concise inspection.

Thanks for the impressive report, I will definitely recommend you